Bill of material is list of raw material and operations through which raw material is processed in process of getting converted into finished good.

So bill of material in made for finished good and sub-assembly (for which separate production order is raised).

For making bill of material for an item, there are pre-requisites.

1. It should be stock item.

2. In item master, following production related values should be selected.

> Allow bill of material - Yes

> Allow production order - Yes

To make BOM, go to:

Module >> Production >> Bill of Material >> New Bill of material

Bill of material form for separate tab for finished goods details, operations and finally materials detail.

Basic item detail:

It will list production item for which bill of material is made. BOM for will raw material required for making quantity mentioned in field above.

If default UOM checked, it will be updated in item master also.

BOM operations detail:

Operations table will list work stations in which your raw material will be processed and convert into finished good.

Operations operating cost will be considered in valuation of BOM also.

To make new work station, go to:

Production >> Work station >> New work station

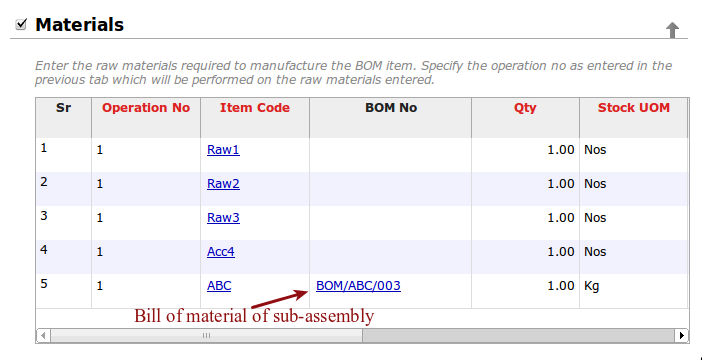

BOM Material list:

It's a list of raw material which will be consumed in production to give finished good. It will list direct raw-materials and sub-assemblies for which separate bom is made. If company does not raise separate bom for sub-assembly item, you can list all the raw material required for sub-assembly in material table itself.

Costing:

Based on operations cost and raw materials rate system will give you bom valuation.

After entering all the detail save and submit this BOM. Only submitted bom will be available for selection in production order.

No comments:

Post a Comment