Wednesday, April 10, 2013

Thursday, November 1, 2012

ERPNext: A Perfect Fit For Distributors & Retailers

Let's understand the business challenges faced by distribution / retails companies and how ERPNext address those challenges.

- Serialize Items:

For company into trading business of consumer durables, its very crucial for them to keep track of each unit in warehouse and store. Misplacing one unit can have big impact on overall profitability as per unit cost of item is high.

ERPNext let's company track items inventory and movement by unique id which is Serial No. On every physical movement of item, it's serial no. is fed into system. Looking at Serial Nos. log, one gets complete idea of station item has been through.

- Point of Sales:

Most of the retail business have to opt for POS software which is not integrated with enterprise application. This leads to duplication of entries from POS application into accounting application to consolidate the income and expenses incurred at different stores.

ERPNext has in-built feature of POS invoicing which does joint entry of Delivery Note, Sales Invoice and Payment Entry in one single transaction. It allows you to define defaults for each store and pull items from barcode scanning.

Since POS is integral and online feature of ERPNext, it provides real-time data to management on billing happening at stores. Invoicing at same time also post GL entries in accounting ledger, hence provides real-time financial standing of each store.

- Multiple Store and Warehouse:

ERPNext is fully scalable to meet requirement of your growing business. You can add unlimited retails stores, warehouses and users in single erpnext account. On opening of every store and warehouse, just add them in system, plug computer with internet connection and newly opened store, warehouse is in complete sync. No need setup hardware and infrastructure at new location. - Sales - Inventory - Accounts Integration:

The integrated ERP application helps user track the pending orders to be delivered and billed to customers. When dealing with other corporate, delivery and billing is not happening at same time. The integrated software lets you book Sales Order when customer confirms an order. Against Sales Order, systems allows you to make partial delivery as and when its happening and get report on pending orders to be delivered. - After Sales Support:

Consumer durable equipment always needs timely maintenance support. The serialized inventory and support module of ERPNext helps you track warranty and AMC expiry of each item sold. Using Support Ticket, you can track customers queries in the system, send them auto-reply with unique support ticket id. Using Customer Issue, you can manage Open, In Progress and Resolved queries of customers.

Best,

ERPNext Team

http://erpnext.com

Monday, July 2, 2012

How to Use Payment Reconciliation Tool?

Payment reconciliation is a tool to define the invoice in unadjusted payment entries (journal voucher). Let's consider an scenario to understand this query.

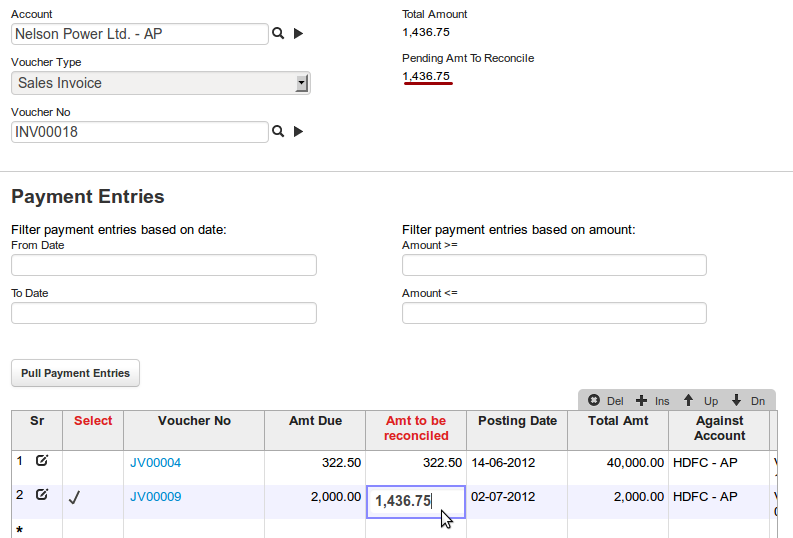

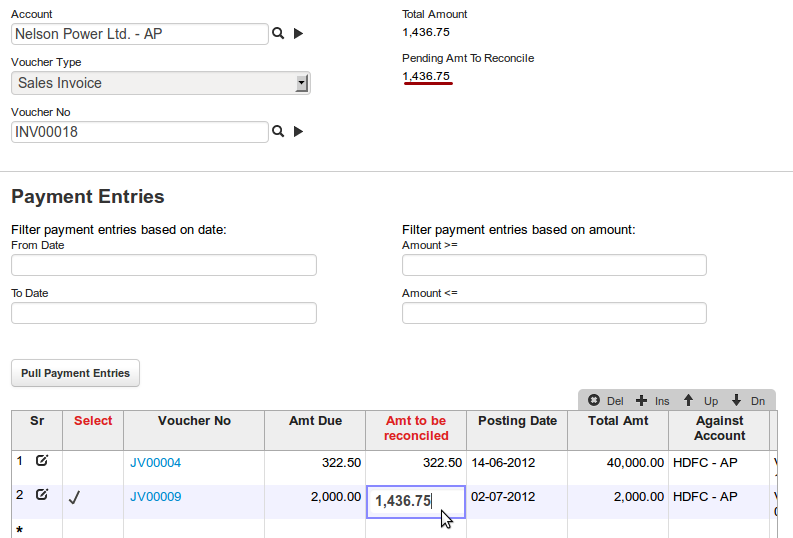

Looking at above given screen-shot, we can try and learn how payment reconciliation works.

INV00018 is the sales invoice worth 1,436.75. There has been no payment entry against invoice hence its 100% invoice is outstanding.

Table below has pulled up all the unadjusted payment entries with amount still not reconciled against any invoice. To reconcile the said amount against invoice INV00018, they will need to check box against JV and click on “Reconcile” button.

Clicking on reconcile button will update invoice no. in unadjusted journal voucher.

Thanks,

ERPNext Team

www.erpnext.com

Looking at above given screen-shot, we can try and learn how payment reconciliation works.

INV00018 is the sales invoice worth 1,436.75. There has been no payment entry against invoice hence its 100% invoice is outstanding.

Table below has pulled up all the unadjusted payment entries with amount still not reconciled against any invoice. To reconcile the said amount against invoice INV00018, they will need to check box against JV and click on “Reconcile” button.

Clicking on reconcile button will update invoice no. in unadjusted journal voucher.

Thanks,

ERPNext Team

www.erpnext.com

Tuesday, June 12, 2012

How to Manage Serial Nos. in ERPNext?

Serial nos. are the unique code assigned to each items. With serial nos.

item detail and its location is tracked. Serial nos. is generally

tagged for item which requires after sales services on it. Hence,

businesses mention serial nos. in invoice based on which items delivery

and warranty status is updated. In case of after sales service, company refers to serial no. to check invoice and purchase detail of that

particular unit of an item.

Note: ERPNext doesn't have functionality to generated barcode for serial nos. Hence you will need to use third party application to manage generate barcode for serial nos.

Let's consider an example of company in sales of desktop and laptop computer. As there is warranty and after sales services provided on items they assign serial nos. on each unit they purchase or assemble.

Status of serial nos.

How to make item a serialized item?

Its defined in item master. In Item >> Inventory detail >> Has Serial no., selecting "yes" will make it serialized item.

How serial nos. get assigned to each unit of a item?

Serial nos. are assigned as soon as company acquires that item. The transaction made while receiving items are purchase receipt a.k.a GRN (in trading) and backflush (in production).

Let's consider a scenario when company places an order for 10 units of serial nos. and making a receipt for the same. When making purchase receipt, user will need to define serial nos. for serialized item based on receipt qty. If 10 qty of PC received, then user will enter / scan 10 serial nos. in serial no. column of that item.

Based on the serial nos. of items mentioned in purchase receipt, on submission system will created a unique serial no. record for each unit of an item. Also status for serial no. is set as as "in store" which will also reflect in stock level report.

Inventory of serialized item is tightly integrated with qty of serial nos. in warehouse. In stock level report for item in particular warehouse will be qty of serial nos. with status as "in store". So, if item A has 5 qty in warehouse X. It means that there are 5 serial no. for that item with status "In Store".

There are multiple possible actions which can be taken over serial no. in store. It can be delivered or issues for production (as raw-material).

Delivery Note:

When making delivery note of serialized item you will need to mention serial nos. equivalent to items quantity. On submitting delivery note serial nos. status will change to "Delivered". Also, based on days of warranty mentioned in item master, system will calculate exact warranty expiry dates starting from delivery date.

There could also occur a scenario where sales bom is created for an item. And one of the child item is serialized. In that case, in delivery note, sales bom item will be in main item table but that itself is not serialized item. And child item will be listed in packing details table. You will need to provide child items serial no. in packing details serial no. column.

Material issue:

In case of material issue you will need to provide serial nos. which will be consumed while manufacturing of finished good.

Note: ERPNext doesn't have functionality to generated barcode for serial nos. Hence you will need to use third party application to manage generate barcode for serial nos.

Let's consider an example of company in sales of desktop and laptop computer. As there is warranty and after sales services provided on items they assign serial nos. on each unit they purchase or assemble.

Status of serial nos.

- In store - Available for delivery / material issue. Updated when submit GRN or enter serial no. manually.

- Delivered - Delivered to customer. Updated when submit serial no.

- Purchase return - These are the serial nos. which are returned back to customer.

- Not in use - Are the units which were define purchase receipt but then canceled due to some reasons. These are the serial nos. which becomes active if tagged in purchase receipt or material receipt again.

How to make item a serialized item?

Its defined in item master. In Item >> Inventory detail >> Has Serial no., selecting "yes" will make it serialized item.

How serial nos. get assigned to each unit of a item?

Serial nos. are assigned as soon as company acquires that item. The transaction made while receiving items are purchase receipt a.k.a GRN (in trading) and backflush (in production).

Let's consider a scenario when company places an order for 10 units of serial nos. and making a receipt for the same. When making purchase receipt, user will need to define serial nos. for serialized item based on receipt qty. If 10 qty of PC received, then user will enter / scan 10 serial nos. in serial no. column of that item.

Based on the serial nos. of items mentioned in purchase receipt, on submission system will created a unique serial no. record for each unit of an item. Also status for serial no. is set as as "in store" which will also reflect in stock level report.

Inventory of serialized item is tightly integrated with qty of serial nos. in warehouse. In stock level report for item in particular warehouse will be qty of serial nos. with status as "in store". So, if item A has 5 qty in warehouse X. It means that there are 5 serial no. for that item with status "In Store".

There are multiple possible actions which can be taken over serial no. in store. It can be delivered or issues for production (as raw-material).

Delivery Note:

When making delivery note of serialized item you will need to mention serial nos. equivalent to items quantity. On submitting delivery note serial nos. status will change to "Delivered". Also, based on days of warranty mentioned in item master, system will calculate exact warranty expiry dates starting from delivery date.

There could also occur a scenario where sales bom is created for an item. And one of the child item is serialized. In that case, in delivery note, sales bom item will be in main item table but that itself is not serialized item. And child item will be listed in packing details table. You will need to provide child items serial no. in packing details serial no. column.

Material issue:

In case of material issue you will need to provide serial nos. which will be consumed while manufacturing of finished good.

Monday, May 14, 2012

Account Payable & Receivable Reports

The accounts payable report provides detail of the money owed by the

business in due format. The total amount owed per supplier per invoice is provided. Also, you can set aging in report like amount to be paid in next 0-30 days, 30-60 days etc.

The accounts receivable report gives you a detailed listing of the balance due over customer per invoice. This helps company follow customer for pending payment against specific invoices.

To check these report in erpnext, go to:

Account >> Report >> Account payable / receivable reports

What are filters for?

Using date and accounts filter you can filter invoice made between specified time for particular customer / supplier.

-- For more queries, write us on support@erpnext.com --

The accounts receivable report gives you a detailed listing of the balance due over customer per invoice. This helps company follow customer for pending payment against specific invoices.

To check these report in erpnext, go to:

Account >> Report >> Account payable / receivable reports

What are filters for?

Using date and accounts filter you can filter invoice made between specified time for particular customer / supplier.

-- For more queries, write us on support@erpnext.com --

Monday, January 30, 2012

How to Use Tax Inclusive Rate Functionality in ERPNext?

Tax inclusive rate functionality allows user to enter tax inclusive rate items rate table.

As per the standard, user has to enter items rate before tax in pricelist which is fetched in items ref rate.

But for company into retail business, users only know tax inclusive rate of an item. They can use this feature which will back calculate tax and ref rate for them.

To back calculate taxes from tax inclusive rate, you will need to:

1. Mention taxes applicable on item level.

2. Tax inclusive rate in rate / basic rate column on item level.

3. Mention all the possible tax ledgers in tax table and check mark "include in print rate".

P.S.:

When need to calculate discount:

When need to offer discount to customer, mention tax inclusive rate in ref rate instead of basic rate.

As per the standard, user has to enter items rate before tax in pricelist which is fetched in items ref rate.

But for company into retail business, users only know tax inclusive rate of an item. They can use this feature which will back calculate tax and ref rate for them.

To back calculate taxes from tax inclusive rate, you will need to:

1. Mention taxes applicable on item level.

2. Tax inclusive rate in rate / basic rate column on item level.

3. Mention all the possible tax ledgers in tax table and check mark "include in print rate".

P.S.:

When need to calculate discount:

When need to offer discount to customer, mention tax inclusive rate in ref rate instead of basic rate.

Monday, January 23, 2012

How to Manage Production Order?

Production order is confirmation for production to start moving resources and process raw materials to get finished good.

To create new production order, go to:

Production >> Production Order

Let's check submitted production order which will help us understand the feeding data in and next steps after raising production order.

1. Its an item which will be produced.

Transfer material:

To create new production order, go to:

Production >> Production Order

Let's check submitted production order which will help us understand the feeding data in and next steps after raising production order.

1. Its an item which will be produced.

2. For this production order, selected bill of material will be considered. Items listed in selected bom will reduce once production completes.

3. FG warehouse: Its a finished good warehouse where finished good when produced completely will be transferred.

4. WIP warehouse: Its a warehouse where production will take place. You will need to create your shop floor as WIP warehouse. All your raw-material will be brought into WIP warehouse only.

5. Consider SA (sub-assembly) item: This field has two options, yes / no.

If select yes, you will need to transfer sub-assembly as one unit of item. You should be selecting yes only if you separately maintain stock of sub-assembly.

Select No if you don't maintain the stock of sub-assembly. If no select, in material transfer, it will pull child item mentioned in bom of sub-assembly.

Once production order is submitted, you will find next steps button which starts with material transfer.

Transfer material:

This transaction actually takes place in stock entry, where all the raw-material will be pulled from selected BOM.

Target warehouse will be WIP warehouse selected in production order. User will select source warehouse based on the actual stock level for that raw material item.

After selecting all the information, system will reduce stock level from source warehouse and increase the same in WIP warehouse selected.

Status of production order will change to "in process" once raw material is transferred into WIP warehouse.

Backflush:

Backflush is done when in actual, you have ready finished good to be transferred from shop floor to finished good warehouse. At this stage, your raw material will be considered as consumed.

Backflush:

Backflush is done when in actual, you have ready finished good to be transferred from shop floor to finished good warehouse. At this stage, your raw material will be considered as consumed.

Subscribe to:

Comments (Atom)